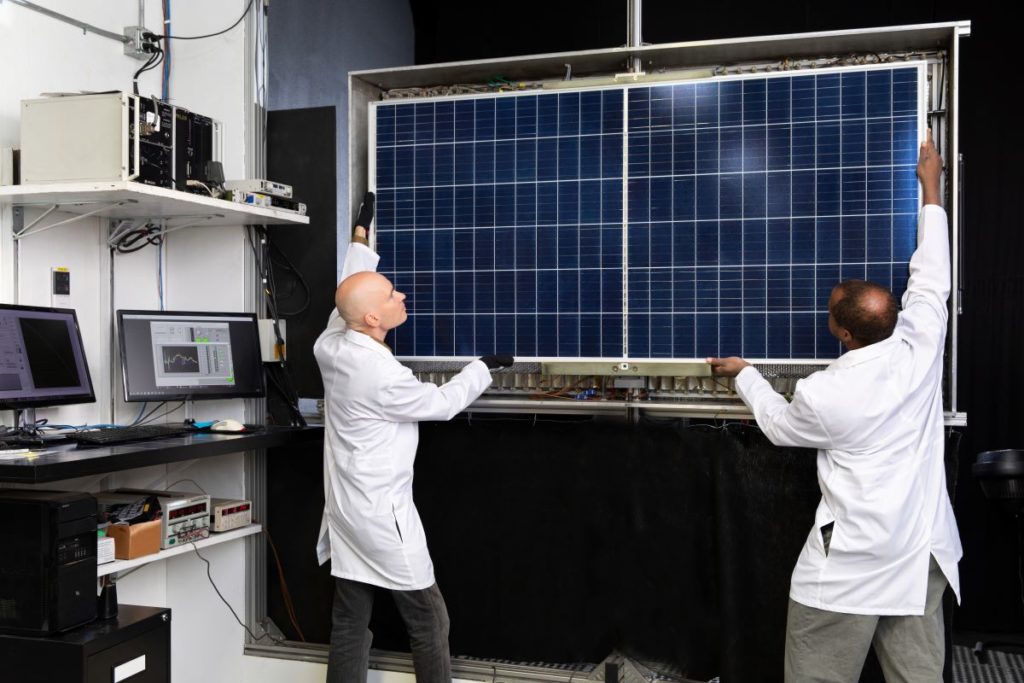

Test lab for solar developers PV Evolution Labs (PVEL) has announced updates to its Product Qualification Program (PQP) with four major changes.

PVEL said notable updates to the PQP include a new test to address concerns around ultraviolet-induced degradation and refocusing the Hail Stress Sequence on identifying the threshold of glass breakage.

Other updates include modifying the Mechanical Stress Sequence to target module mechanical durability concerns, and streamlining processes for light-induced degradation, damp heat, light and elevated temperature-induced degradation, and backsheet durability sequence testing.

“The improvements we’ve made in this PQP update incorporate critical feedback from our downstream partners, research institutes, module and component manufacturers, and our own test results, keeping the PVEL PQP at the forefront of the growing demand for PV module procurement due diligence,” said Tristan Erion-Lorico, vice president of sales and marketing at PVEL.

Erion-Lorico added that the module buying landscape has changed dramatically in recent years with advancements in module technology and new players entering the market. The updated programme is a response to these changes.

PVEL’s PQP testing helps inform the company’s annual PV Module Reliability Scorecard, providing insights for PV module procurement based on data from PVEL’s testing.

In May, PVEL announced that a total of 247 module types from 35 manufacturers had been named “Top Performers” in its 2023 Module Reliability Scorecard, more than doubling last year’s numbers and the highest ever.

This year’s Top Performers were spread across 12 different countries and were produced in Canada, Cambodia, China, India, Malaysia, Mexico, Singapore, South Korea, Thailand, Turkey, the US and Vietnam. Meanwhile, 11 manufacturers had one or more module types be Top Performers in every reliability test, with five of these model types also Top Performers in energy yield (PAN) performance.

However, nearly one-third of the bills of materials (BOMs) tested suffered at least one failure during testing.

After the publication of the Module Reliability Scorecard, PV Tech Premium talked to Erion-Lorico about the emerging trends and themes from this year’s scorecard, differences between glass-glass and glass backsheet and how the increased power loss in the potential-induced degradation testing.

(The above content is reproduced from pv-tech,BySimon Yuen)

Disclaimer: This website reproduces information from cooperative media, institutions or other websites. The publication of this article for the purpose of transmitting more information,and it does not imply endorsement of its views or confirmation of the authenticity of the content. All information on this website is for reference only and can’t be used as the basis for transactions or services. If there are any infringement or other issues in the content of this website, please notify it in time, then this website will be promptly modified or deleted. Anyone who logs in to this website in any way, or directly or indirectly uses the information on this website shall be deemed to have voluntarily accepted the binding of this website statement.