| Item | Parameter |

| Cell type | 156mm-210mm/5BB-12BB |

| Panel Size | 2500*1400 |

| Busbar specification | Bus bar is in roll feeding and automatic cutting, thickness 0.18-0.45mm, width4, 5、6、8mm, roller weight≤13Kg |

| Cycle time | 20s for conventional version, 25s for bypass welding |

| Fragment rate | <0.2‰ |

| Soldering method | electromagnetic |

| Lead busbar angle and deviation | 90° deviation ≤2° |

| The overlap area of bus bar | ≥80%, and the deviation is within ± 1 mm |

| Overlap deviation of bypass bus belt | ±1mm |

| secondary string layup accurancy | ±0.25mm |

| Maintenance rate | ≥98% |

| Overall dimensions:(L*W*H) | 4930 ×4613×2641mm |

| Voltage | 3Phase 5 wire 380V,50Hz,AC±20% |

| Power | 22KW |

| Air Pressure | 0.6-0.8MPa 2.0m3/min |

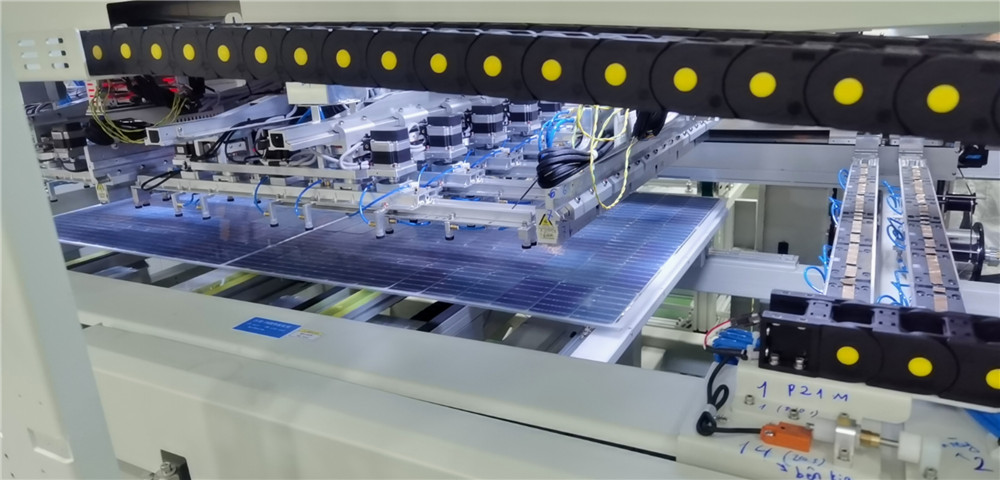

2. Technical Performance of Automatic Bussing Machine

1). Adopt the method of separating the cell string from the glass, and grab the cell string in the air,then to interconnected solder the head, middle and tail bus bar of the middle wire edition module at a certain height.

2).bypass bus bar for 1 / 3 5-series modules of 210 cells. shaped bus end punching function.

3). It has the function of rolling bus belt supply, upward bending u, L-shaped lead wire and u, L-shaped bus end punching function.

4). It has the function of bus belt drilling, which can be turned off.

5).The assembly line in front of the welding machine must have the function of normalization.