Exhibition summary | HORAD 2025 Shanghai SNEC Exhibition has been successfully concluded, innovative intelligent manufacturing empowers a low-carbon future!

The 2025 Shanghai SNEC Photovoltaic Exhibition came to a successful conclusion. HORAD, a global leader in photovoltaic intelligent equipment, has attracted the attention of the theme booth with the "Glory the Future, Intelligent Construction Zero Carbon". With its intelligent manufacturing solutions in the entire industry chain, hard-core digital and intelligent equipment matrix and deep technical accumulation and innovation strength, it won the "Technology Achievement Award" of the 2025 APVIA Asia Photo Storage Award, fully demonstrating its technological leadership as the world's leading photovoltaic intelligent equipment manufacturer, empowering global energy transformation with innovative intelligent manufacturing capabilities, and drawing a new picture of the zero-carbon future.

Three core products unveiled, defining a new height of photovoltaic intelligent manufacturing

Automatic retrieval machine: cracking pain points, improving quality and reducing costs

In response to the problem of photovoltaic module remediation, this equipment achieves technological breakthroughs through integrated integrated design.

Functional integration: two-in-one production and rework functions, leading the industry in equipment integration;

High yield and high efficiency: 50s/16-gate single-piece replacement, and the re-repair yield can be increased by more than 50%;

High compatibility: compatible with 5-24 gate SMBB, 0BB and other components of different specifications;

High-precision detection: EL and appearance re-check on incoming materials, conduct single-piece EL and appearance inspection after welding, and perform secondary re-checking to ensure yield after re-work;

Repair method: The laser welding power is stable and reliable, and it does not damage the battery.

Coating machine: Full-chain intelligent control, the cornerstone of photovoltaic new quality productivity

The full technical route covers: iterating through single-junction to stacked battery technology, modular design adapts to laboratory-level mass production, empowering enterprises to have full-cycle technical layout and capacity transition.

Intelligent environmental control: The process is stable and reliable, the customized glove box is deeply integrated with the automation system, build a strict production environment, accurately control key parameters such as temperature and humidity, gas composition, etc., and ensure the stability of the perovskite coating process. At the same time, the integration of automatic liquid supply, loading and unloading modules achieves efficient production capacity output of 200MW stacked battery cells annually, meeting the needs of large-scale industrial production.

Intelligent and effective dual advantages: With the help of the linkage between sensors and intelligent control systems, human operation errors are reduced and production accuracy is greatly improved. At the same time, the intelligent operation model significantly improves production efficiency, reduces labor costs, and enhances the core advantages of enterprises in market competition.

Customized collaborative operations: Excellent adaptation performance, equipped with customized VCD and synchronized with glove boxes, accurately adapting to the perovskite coating process characteristics, from equipment configuration to functional coordination, meet the special needs of the photovoltaic perovskite field in all aspects, and provide solid guarantees for product quality and production efficiency.

Laser junction box welding machine: precision and efficiency, reshaping process standard

With its outstanding performance such as precision controllability, strong adaptability, and low energy consumption, HORAD laser junction box welding machine has become a new benchmark for efficient and intelligent welding in the new energy industry. Compared with traditional hot-pressure shaping welding and electromagnetic welding, the pulling force after laser welding is increased by two times (greater than 160N), the yield is increased by 0.2-0.3%, and the cost per component is reduced by at least 0.3-0.5 yuan. Effectively improve production efficiency and product stability, and reduce cost losses caused by rework or scrapping.

Turnkey engineering services, empowering all process routes

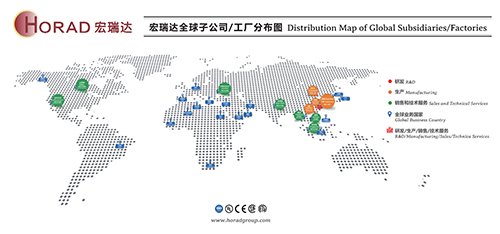

As a global leader in photovoltaic intelligent manufacturing equipment, HORAD provides intelligent manufacturing solutions for the entire industry chain, covering all process routes, deeply adapted to mainstream battery technology feeding systems such as BC/HJT/TOPCon/perovskite, and also achieved full coverage of seven major process routes such as PERC/TOPCon/HJT/perovskite/BIPV in the field of back-end packaging, creating the industry's top technical matrix and delivery capabilities.

Breakthrough in the perovskite field: customized whole line delivery, breaking industry record

As a pioneer in perovskite industrialization, HORAD breaks through the industry boundaries with customized whole-line delivery capabilities: the world's first GW-level extreme electro-optical energy production line achieves "turnkey" full-process empowerment, driving the industrialization of perovskite technology; BOE's pilot line project has also set a new benchmark with 38-day fast delivery, and injects acceleration into customer business implementation through full-process independent, automation and intelligent production line construction, demonstrating the leading strength of the new generation of photovoltaic technology and equipment field.

Fully automatic packaging line: innovation and upgrade, cost reduction and efficiency improvement

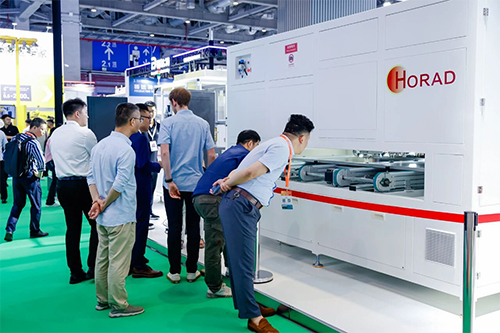

In addition to core production equipment, HORAD fully automatic packaging line has also become the highlight of the exhibition. The production line has the core advantages of high automation, small footprint and wide compatibility. It can achieve standardization of packaging processes through precision control systems, significantly improving packaging consistency, while reducing manual intervention and reducing comprehensive costs, providing strong support for the intelligentization of the entire process of photovoltaic manufacturing.

The world's first flat plate laminate technology, defining the "new era of hard pressing"

"On June 12, HORAD held a new product launch conference with the theme of "Hard Pressure New Era" and launched the world's first flat plate laminate. Through innovative structural design, intelligent temperature control system and high-efficiency material application, this technology has achieved a 30% increase in the accuracy of the lamination process, a 25% reduction in energy consumption, and a significantly shortened production cycle. The annual cost reduction of a single GW can reach 5 million yuan. This technology will promote the upgrading of photovoltaic module manufacturing to a more efficient and environmentally friendly direction, providing key support for the global photovoltaic industry to reduce costs and increase efficiency.

Using technological innovation to draw a zero-carbon future together

At this exhibition, HORAD booth received hundreds of customers from Europe, America, Asia Pacific, Middle East and other regions, and reached cooperation intentions with many customers. In the future, HORAD will continue to use "hard-core technology" as the engine. HORAD will continue to deepen technological innovation and be guided by customer needs to provide global photovoltaic companies with more efficient and smarter equipment solutions, and promote the photovoltaic industry to a higher quality development stage.